In the production of high-quality ceramic slabs, the raw materials used must meet strict requirements to ensure consistency, strength, and outstanding aesthetic performance. Whiteness level, shrinkage control, and fusibility are key factors to consider when developing new mineral solutions. Let’s explore the results of the research conducted by Imerys.

In recent years, large format ceramic slabs have continued to gain ground in high-end architecture and interior design, now going well beyond their traditional use in flooring and wall tiles. Today, these oversize formats are being widely used for premium and innovative architectural applications such as high-end aesthetic countertops, wall cladding, furniture, and seamless ventilated façades used for upmarket buildings and houses. As a result, demand for higher quality slabs demonstrating superior technical performance is growing - particularly in markets like Spain, where prices for these materials continue to rise.

Produced using advanced production technologies, these continuous surfaces must demonstrate exceptional consistency, strength and aesthetics, placing high demands on the raw materials they rely on. Imerys develops mineral solutions tailored to the specific requirements of the high-end large slab market. Working closely with customers, the company focuses on key performance levers such as whiteness, shrinkage control and fusibility - as well as delivering solutions adapted to new technologies and that meet customers’ sustainability and quality challenges - all essential in today’s competitive and fast-moving market.

Ultrawhite minerals for vibrant design and premium finishes

Ceramic bodies

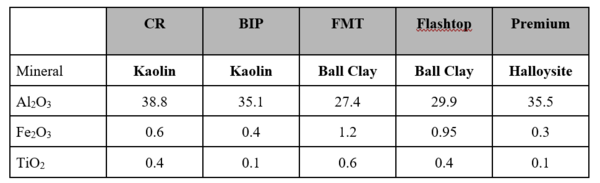

Ceramic slab finishes that imitate natural stone, marble or concrete are extremely popular with architects and homeowners alike. Body whiteness is key to achieving these finishes, as it directly affects the brightness, color fidelity and overall surface appearance of the finish. Imerys offers a wide portfolio of very pure white kaolins, ball-clays and halloysites, tailored to ceramic slab body formulations:

- CR (Brazil) and BIP (FR) kaolins are benchmarks for their high purity and consistent whiteness.

- French ball clays FMT and Flashtop offer both whiteness and plasticity.

- High whiteness New Zealand Halloysite provides high whiteness and mechanical resistance.

Alumina, Iron and Titanium oxides contents of Kaolin and Halloysite

These values do not represent a specification. Since the products are based on naturally occurring materials, Imerys reserves the right to change these data if necessary.

Engobes and smaltobbio

Imerys’ new Whitewave premium ball clays are specifically formulated for use in engobes and smaltobbio vitrified engobes. Produced in the UK, Whitewave delivers an ideal combination of whiteness, opacity and flowability, while providing excellent adherence to the substrate and a flawless white base for traditional or digital color application. Imerys’ technical support team can help producers optimize the use of Whitewave in their processes.

Optimized feldspar solutions for shrinkage reduction

Minimizing shrinkage is critical in large slab production. In addition to lowering raw material costs and increasing production yield, it contributes to reducing dimensional variations that can lead to costly slab breakages further down the supply chain.

Widely used by large slabs’ producers, Imerys’ flagship feldspar, RF4, is a proven solution for reducing shrinkage. For example, compared to standard feldspars sourced from Turkey and Italy, a formulation containing 20% RF4 feldspar enables manufacturers to achieve 0,5 to 0,8% shrinkage reduction and up to 1 to 1,2% when introduced at 30-35%. This shrinkage reduction translates into a reduction in the raw material consumption to produce a given surface of tiles.

RF4’s unique composition acts on three levels:

- Its optimized pressability improves packing density.

- Its improved thermal stability allows for a wider firing window.

- It promotes the formation of low-density phases.

Additionally, Imerys’ lithium feldspar fusibility additive, B44, can be used at a 5-8% loading to reduce shrinkage while increasing the fusibility of the formula.

High-fusibility minerals for faster firing and lower emissions

Reducing firing time and/or temperature is another priority in manufacturers’ quest to lower energy consumption and emissions. Imerys offers a full range of high-fusibility talcs that promote early vitrification while improving the density and mechanical performance of ceramic bodies. A new low-carbon talc has also recently been launched to eliminate black core formation and improve tile surface quality - particularly in ultra-white porcelain applications.

When combined with zirconium silicate and alumina, Imerys talcs can significantly increase brightness and whiteness in super-white formulations.

Micronized minerals for new colormaking processes and technologies

As digital glazing becomes more widespread, it places new demands on raw materials. Imerys is actively developing a new generation of micronized French kaolins, talcs and wollastonites for glaze and colour manufacturers, optimized to meet the precision requirements of digital equipment - with a full product range expected by 2026.

Optimized logistics through new platforms

To support customers in key ceramic regions, Imerys has recently opened two new logistics platforms in Castellón, Spain, and Wilaya de Béjaïa, Algeria through Argerys, in addition to its existing platform in Italy.

These platforms allow Imerys to stock high-demand raw materials closer to ceramics clusters, improving responsiveness and service reliability. In addition, they provide customized blending services to meet local customers’ specific raw material needs. Equally importantly, they reduce the environmental footprint of the supply chain. For example, French kaolins, such as K1C, produced at the Ploemeur site in Brittany, France, are now shipped to Castellón by sea, and only the last leg of the journey is made by truck. Prior to this, shipments traveled the entire route by road. This represents a saving of almost 1,000 T CO2eq per year.

A commitment to sustainability

In addition to meeting customers’ technical requirements, Imerys has made a firm commitment to reducing its own environmental footprint as well as supporting its customers in their transition to a low carbon economy.

The strategic location of the company’s plants and logistics platforms near important ceramics clusters helps cut greenhouse gas emissions by shortening transport distances and optimizing supply chains. At the same time, Imerys’ ownership of mining assets across Europe ensures full traceability of raw materials, increases transparency and fosters more responsible and efficient supply chain management.

Imerys is also making strides toward its own sustainability goals:

- By the end of 2024, the company had already achieved a 28% reduction in Scope 1 & 2 greenhouse gas (GHG) emissions, and a 15% reduction in Scope 3 GHG emissions compared to its 2021 baseline.

- By the end of 2025, it aims to assess the sustainability performance of the majority of its products - initially focusing on those which contribute to 75% of its turnover - underscoring the company’s ambition to be a partner of choice for customers.

As ceramic manufacturers adopt increasingly demanding formats, finishes, colors and technologies, the need for advanced, reliable raw materials continues to grow. Imerys is committed to helping its customers stay competitive in the expanding large-format segment by delivering high-performance mineral solutions, local supply and technical support, and materials adapted to evolving processes and technical requirements.

Stay updated on the industry with curated data and insights each month: subscribe to the TECNA Magazine

POWERED BY CWR

PUBLICATION

04/02/2026